bronze castings will have many defects during the casting process, so we must be professional and careful when casting. Here we introduce the common casting defects:

1. Sand holes: insufficient strength of the molding sand; insufficient compactness of the molding sand; too fast pouring speed, etc.; 2. Porosity: excessive moisture in the molding material or a large amount of gas-generating substances; poor air permeability of the molding sand and core sand; too fast pouring speed; 3. Shrinkage holes: poor shrinkage compensation during the solidification process of the casting; 4. Cracks: large difference in casting wall thickness; improper opening of the pouring system; poor concession between the sand mold and the core 5. Sticky sand: poor refractory of the molding sand or too high pouring temperature, etc.

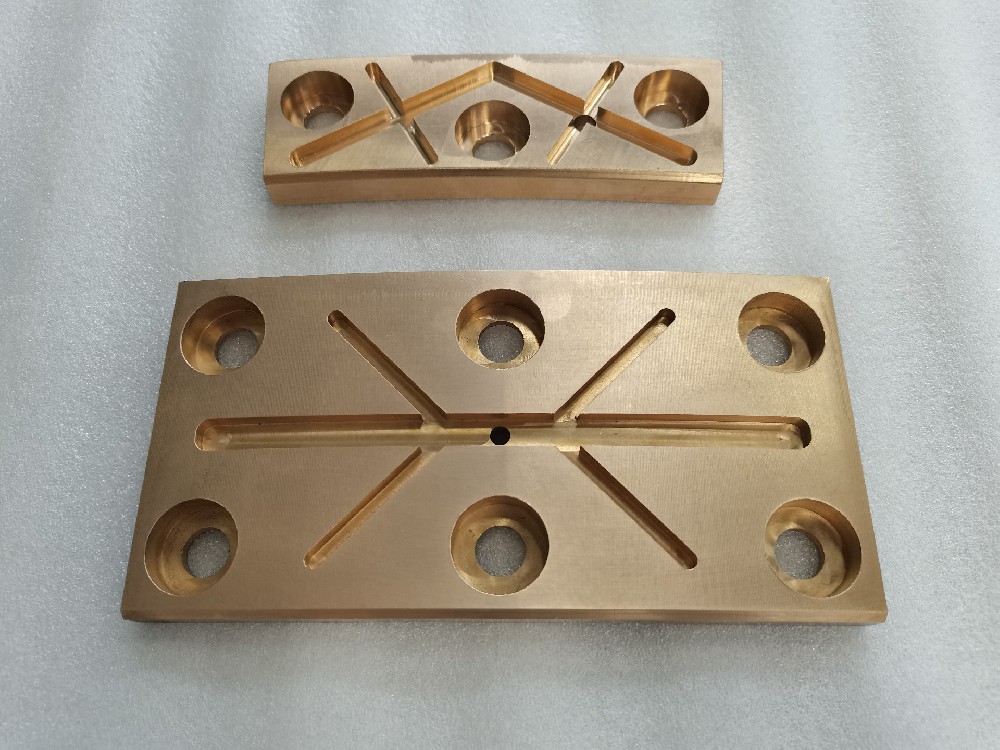

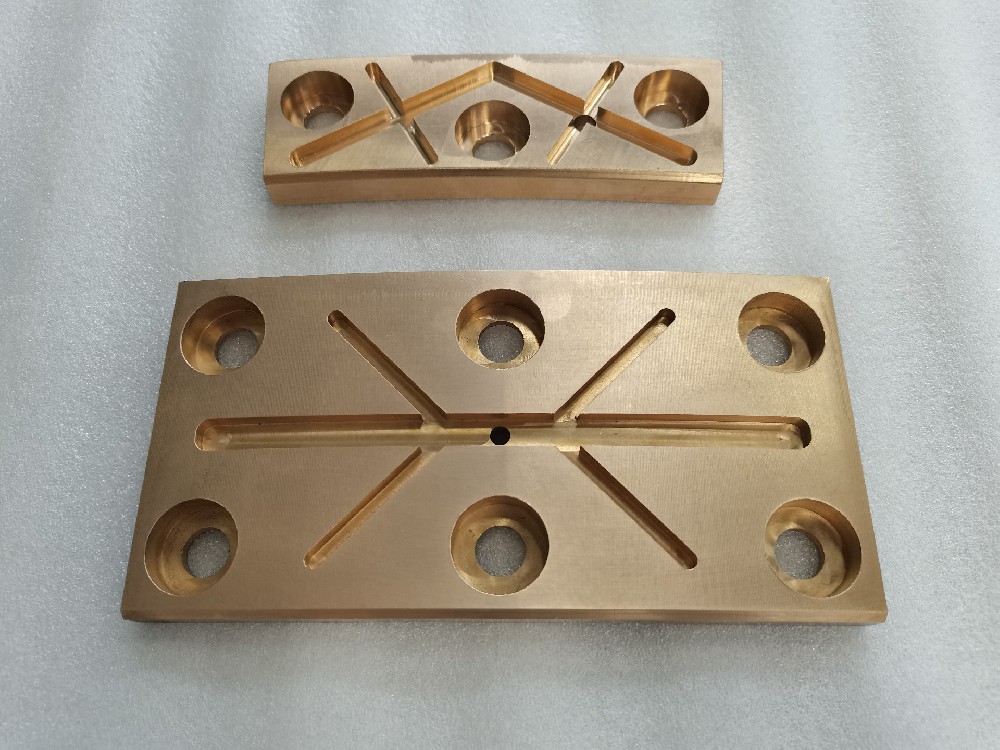

bronze castings

What are the characteristics of the materials of bronze castings?

ZCuSn10Pb1

It is a typical tin-phosphor bronze with high hardness and wear resistance. It can be used to manufacture parts that work under heavy loads, high speeds and high temperatures and are subject to strong friction, such as connecting rod bushings, gears, worm gears, etc. High hardness, excellent wear resistance, not easy to produce seizure phenomenon, good casting performance and cutting performance, good corrosion resistance in the atmosphere and fresh water. The bronze sleeves produced by Dashan can be used for wear-resistant parts working under high load (below 20Mpa) and high sliding speed (8m/s), such as connecting rods, bushings, bearings, gears, worm gears, etc.

ZCuAl9Mn2, ZCuAl9Fe4

Aluminum bronze has high strength, high density and stable chemical properties. Commonly used in valve bodies, worm gears, nuts, pipe fittings, etc.

ZCuZn25Al6Fe3Mn3

High-strength aluminum brass, the highest strength among special brasses. It has high strength, high hardness, high wear resistance, moderate plasticity and good corrosion resistance. Therefore, it is used to cast high-load wear-resistant weights on heavy machinery

ZCuZn38Mn2Pb2

It has good mechanical properties and corrosion resistance, good wear resistance and good cutting performance. General purpose structural parts, simple castings used in ships, instruments, etc., such as sleeves, bushings, bearings, sliders, etc.

ZCuSn10Pb5 ZCuSn6Zn6Pb3 can be used to manufacture wear-resistant parts such as bushings, gears, worm gears, etc. that work under medium loads and speeds.

Corrosion resistant, especially to dilute sulfuric acid, hydrochloric acid and fatty acids. Structural materials, corrosion-resistant and acid-resistant accessories, as well as crusher bushings and bearings.

ZCuPb10Sn10

Good lubrication performance, wear resistance and corrosion resistance, suitable for use as bimetallic casting materials. Vehicle bearings, bimetallic bearings for internal combustion engines with a load peak of 100Mpa, as well as piston pin sleeves, friction plates, etc.

ZCuPb15Sn8

In the absence of lubricants and water-based lubricants, it has good sliding and self-lubricating properties, is easy to cut, has poor casting properties, and has good corrosion resistance to dilute sulfuric acid. Bearings with high surface pressure and side pressure can be used to manufacture bronze cooling tubes for cold rolling mills, parts with impact load resistance of 50Mpa, bimetallic bearings for internal combustion engines, mainly used for piston pin sleeves with a maximum load of 70Mpa, and acid-resistant accessories.