Izici ezilandelayo kufanele zinakwe ekulungiseni i-welding kanye nokwelashwa okulwa nokugqwala kwe-C86300i-tin bronze bushing ukulingisa:

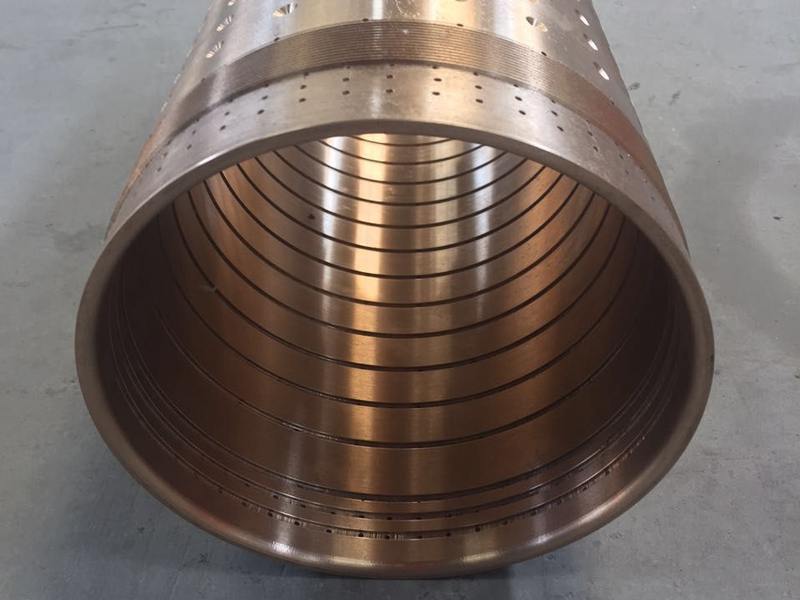

Ukushisela igesi: Sebenzisa ilangabi eliqinile elingathathi hlangothi, amandla elangabi ayafana nawensimbi yensimbi yokushisela igesi, bese ukhetha intambo yokushisela efana ne-homogeneous enokuqukethwe kwethini ngo-1%~2% ngaphezu kwento engumzali.

I-welding rod arc welding: Ikakhulu isetshenziselwa ukuthungatha ukulungisa i-welding, khetha izinduku zokushisela zethusi ze-phosphor noma izinduku ezikhethekile zokushisela i-tin bronze, kanye ne-weld ngemva kokushisa kuqala.

Ukushisela igesi ye-tungsten enert manual: Okuqukethwe kwe-tin yocingo lokushisela kudinga ukuphakama ngo-1% ~ 2% kunempahla engumzali, i-weldment idinga ukushiselwa ngaphambili, futhi ukushisela kwenziwa ngamandla amanje aqondile.

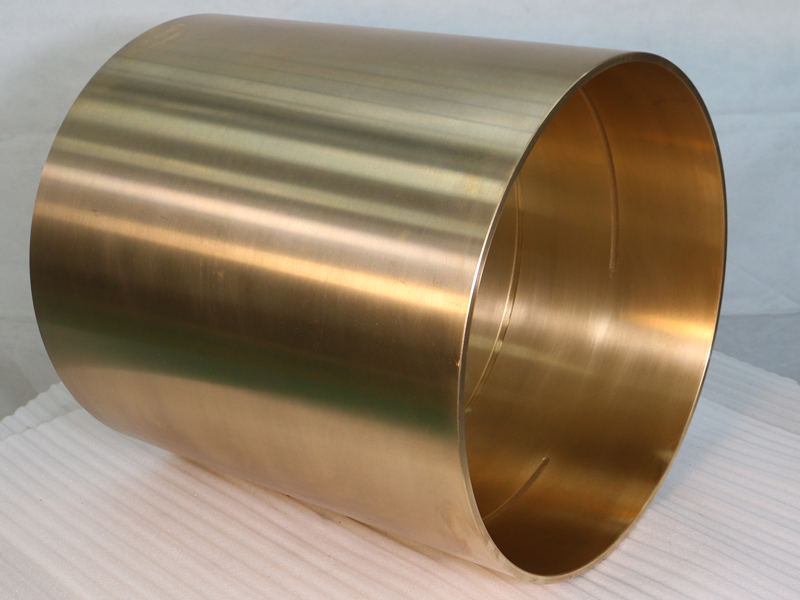

Ukwelashwa kokuhlanza: Hlanza ngokuphelele ubuso bomkhono wethusi ukuze ususe ukungcola okufana namafutha, uthuli, njll.

I-rust-proof coating: Faka i-anti-rust coating, njengopende, i-wax, njll., ukuze uqinisekise ukuthi ukunamathela kufana futhi akushiyi. .

Ukwelashwa kokudlula: Ifilimu ye-oxide eminyene yenziwa phezu komkhono wethusi ngezindlela zamakhemikhali ukuze kuthuthukiswe ukumelana nokugqwala.