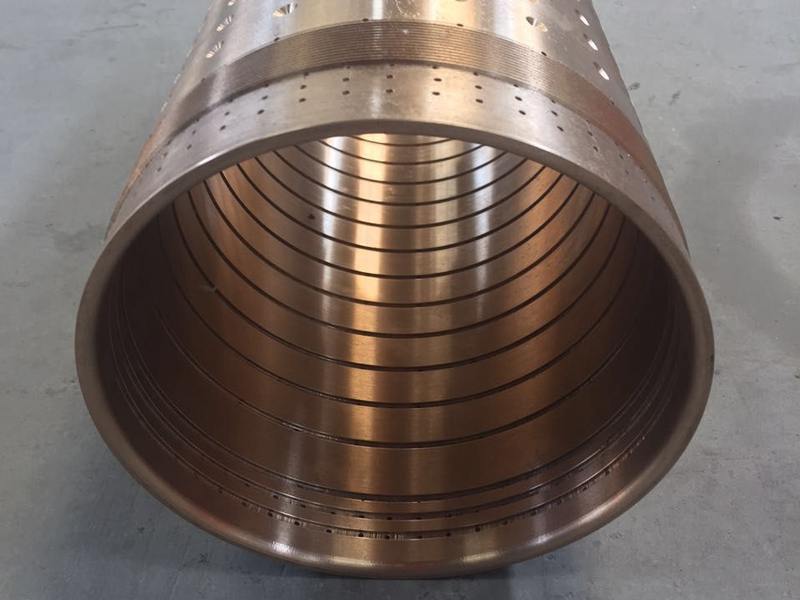

Lintlha tse latelang li lokela ho lebisoa tlhokomelo ho tokiso ea welding le kalafo e khahlanong le mafome ea C86300.sehlahla sa tin boronse castings:

Ho cheselletsa khase: Sebelisa lelakabe le sa nke lehlakore, matla a lelakabe a tšoana le a tšepe ea khase e cheselletsang khabone, 'me u khethe terata ea homogeneous e nang le thini e nang le 1% ~ 2% e phahameng ho feta thepa ea motsoali.

Welding rod arc welding: Haholo-holo e sebelisoa bakeng sa ho tjheseletsa ho lokisa, khetha lithupa tsa phosphor tsa bronze kapa lithupa tse khethehileng tsa tin boronse, le weld ka mor'a ho futhumatsa pele.

Manual tungsten inert gas welding: Likahare tsa tin tsa terata ea welding li hloka ho ba 1% ~ 2% holimo ho feta thepa ea motsoali, weldment e hloka ho futhumatsoa pele, 'me welding e etsoa ka hona joale ka kotloloho.

Kalafo ea ho hloekisa: Hloekisa ka ho feletseng bokaholimo ba letsoho la koporo ho tlosa litšila tse kang oli, lerōle, joalo-joalo.

Ho roala ho thibelang mafome: Tšela seaparo se thibelang mafome, joalo ka pente, boka, joalo-joalo, ho etsa bonnete ba hore seaparo seo se tšoana le ho se sieo. "

Phekolo ea Passivation: Filimi e teteaneng ea oxide e thehoa holim'a letsoho la koporo ka mekhoa ea lik'hemik'hale ho ntlafatsa ho hanyetsa kutu.