The C51100 alloy, known for its high strength and excellent wear resistance, is specifically chosen for this component to ensure extended service life in high-friction and demanding applications.

Casting process:Centrifugal casting, sand casting, metal casting

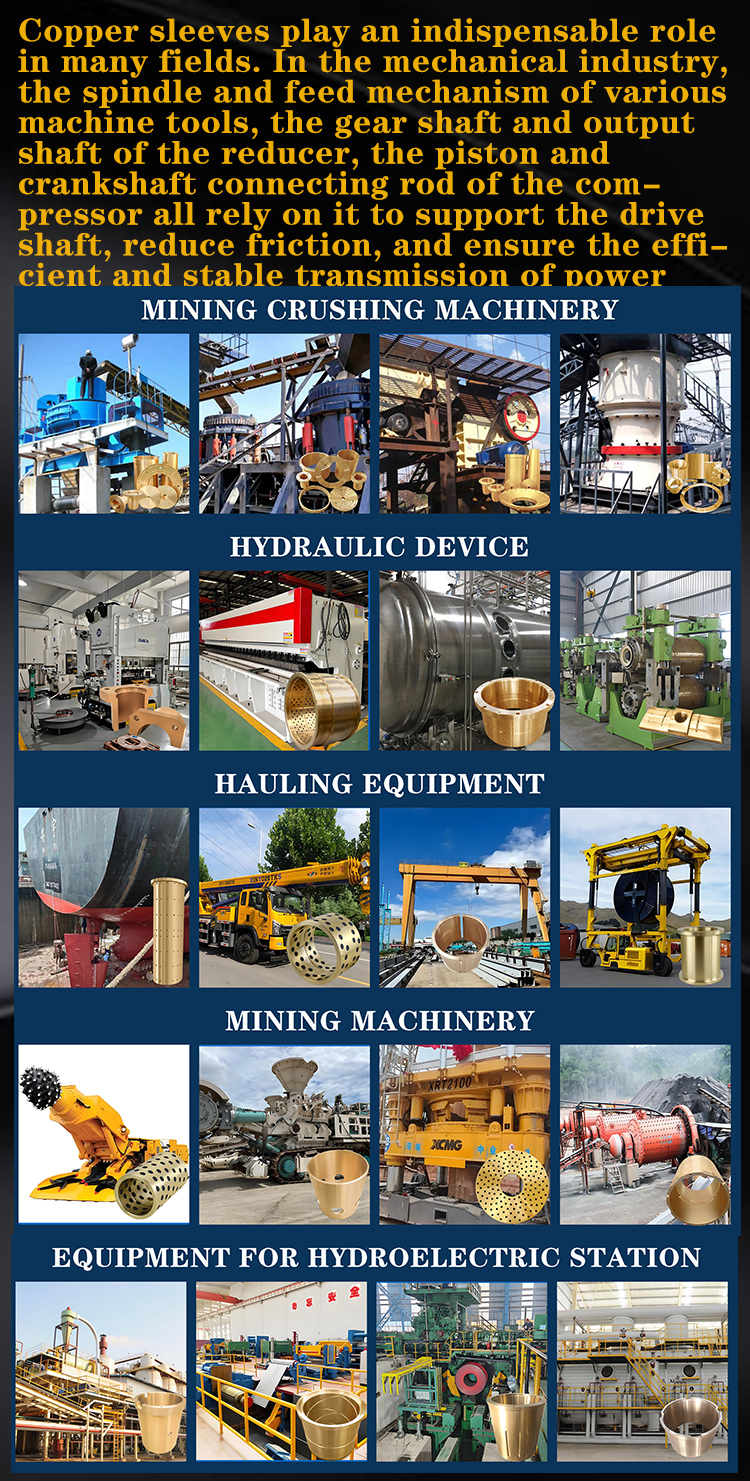

Application:Mining, coal mining, machinery industry

Surface finish:Customisation

Material:Customised copper alloys