C93200 (SAE 660) – High-Lead Tin Bronze

Good machinability, low friction, common for general bushings.

C95400 (Aluminum Bronze)

High strength, excellent wear & corrosion resistance for heavy-duty use.

C86300 (Manganese Bronze)

High load capacity, used in gears and heavy machinery.

C93700 (High-Tin Bronze)

Superior bearing properties for high-speed applications.

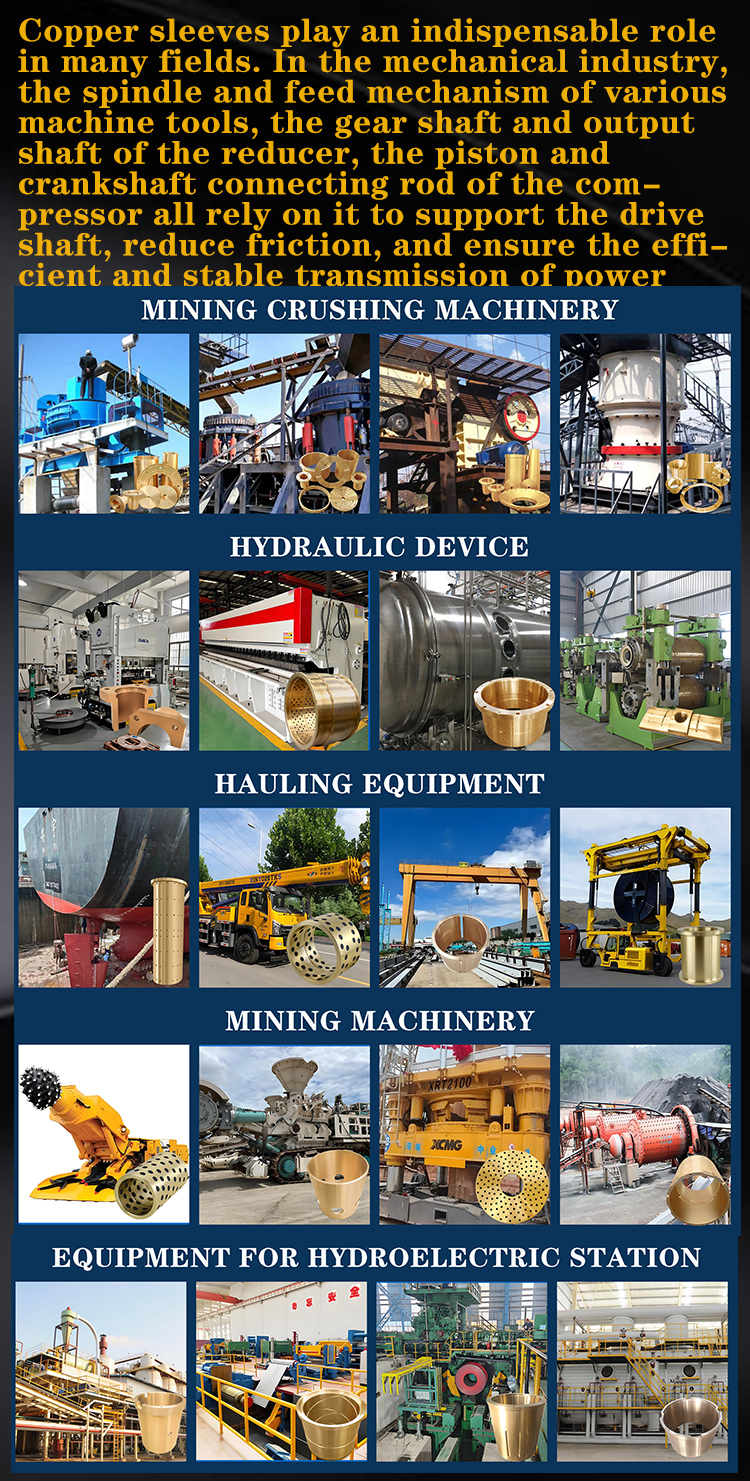

Typical Applications:

Pump & Valve Components (liners, impellers)

Marine Shaft Bearings (propeller shafts, stern tubes)

Mining & Heavy Equipment (crusher sleeves, conveyor bushings)

Industrial Machinery (hydraulic cylinders, gearbox bushings)

Oil & Gas (mud pump sleeves, drilling equipment)

Why Choose Centrifugal Casting Over Other Methods?

Sand Casting → More porous, weaker structure.

Machined from Bar Stock → Higher material waste, less optimal grain flow.

Static Casting → Potential for inclusions and uneven density.

Customization Options:

Inner/Outer Diameter & Length – Precision-machined to fit.

Grooves & Lubrication Channels – For better oil/grease distribution.

Special Coatings (PTFE, Graphite) – For self-lubricating applications.