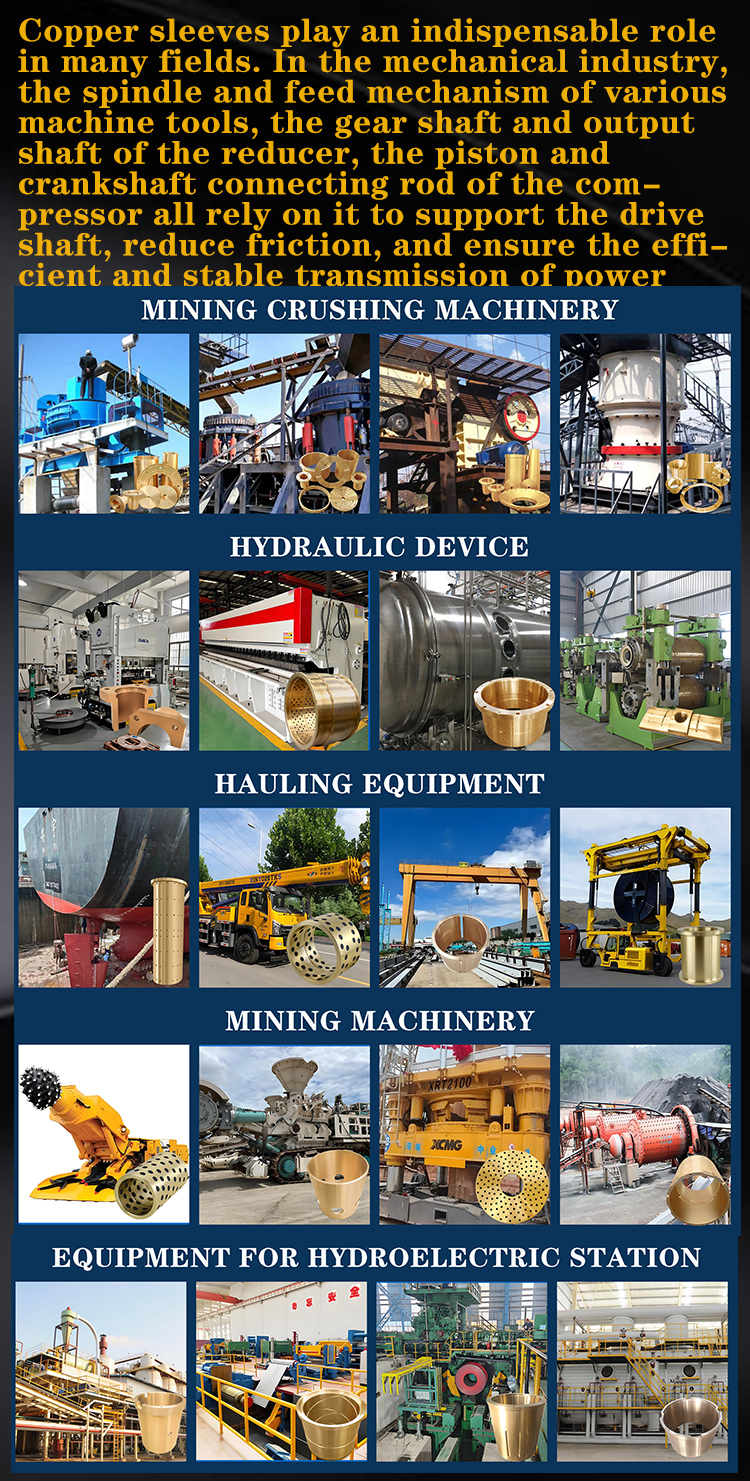

The main function of a sleeve in these harsh environments is to act as a wear liner, bearing surface, or a protective guide for moving parts. Copper and its alloys are selected for a combination of properties that are essential in metallurgical settings:

Excellent Thermal Conductivity: This is the most critical property. Copper alloys rapidly draw heat away from the source (e.g., a hot steel billet or molten slag), preventing the sleeve itself and the equipment it protects from overheating and failing.

High Melting Point (of alloys): While pure copper melts at 1085°C, common alloys like Chromium Copper (CuCr) or Aluminum Bronze (CuAl) can maintain strength at temperatures encountered near molten metal.

Good Mechanical Properties at Elevated Temperatures: They retain much of their strength and hardness even when hot.

Wear and Galling Resistance: Especially important for bearing surfaces. Bronze alloys, in particular, have excellent anti-galling properties against steel.

Corrosion Resistance: Resists oxidation and scaling at high temperatures and is also resistant to certain cooling waters and chemicals.

a) Continuous Casting Machines:

Mold Plates and Liners: The water-cooled mold that molten steel first pours into is often lined with high-conductivity copper or chromium copper plates. While large, these function as liners or sleeves for the cooling system.

Support Rollers and Guides: Sections that guide the solidifying strand of steel use copper-alloy sleeves within rollers to withstand the radiant heat and provide a smooth bearing surface.

Oscillation Marks: The mechanism that oscillates the mold uses large, heavy-duty bronze bushings to handle the extreme load.

b) Rolling Mills:

Bearings and Bushings: In the roll necks (the ends of the rolls that go into the bearing housing). While modern mills use advanced roller bearings, many older and heavy-duty mills still use bronze sleeve bearings because of their high load capacity and ability to embed contaminants.

Guide Boxes and Repeaters: Sleeves and liners that guide the hot bar or sheet through the rolling stands are often made from wear-resistant copper alloys like aluminum bronze.

c) Blast Furnaces and Electric Arc Furnaces:

Cooling Staves: Large copper sleeves are integral parts of cooling pipes and staves that line the furnace walls, carrying water to extract heat and protect the furnace structure.

Tapping Hardware: Components like tuyeres (which blast air into the furnace) and parts associated with the tap hole can feature copper sleeves for their cooling properties.

Electrode Arms: In EAFs, the large arms that hold the graphite electrodes may use high-strength, high-conductivity copper alloy bushings and connectors.

d) Slag Handling and Processing:

Slag Pot Cars: The bearings and bushings on the cars that transport molten slag must withstand heat and abrasive dust. Self-lubricating bronze bushings are common here.