The Role and Importance of Bushing Parts

Bushings, also known as bearing bushings or plain bearings, are primarily used to reduce friction between the shaft and the bearing housing while providing support and positioning functions. Their main roles include:

Reducing Friction and Wear: Bushings reduce direct contact between the shaft and the bearing through lubricating media (such as lubricating oil or solid lubricating materials), thereby minimizing friction loss and extending equipment life.

Support and Positioning: In high-speed mechanical equipment, bushings can effectively stabilize the shaft's operating trajectory, preventing deviation or vibration.

Cushioning and Noise Reduction: High-quality bushing materials can absorb some vibrational energy, reducing noise during equipment operation.

If the bushing quality is poor, it may lead to premature wear of the equipment, unstable operation, and even cause serious failures. Therefore, choosing high-precision, high-wear-resistant bushings is crucial.

Manufacturing Processes of Bushings: Centrifugal Casting and Gravity Casting

The performance of bushings largely depends on their manufacturing process. Currently, the mainstream bushing production processes include centrifugal casting and gravity casting:

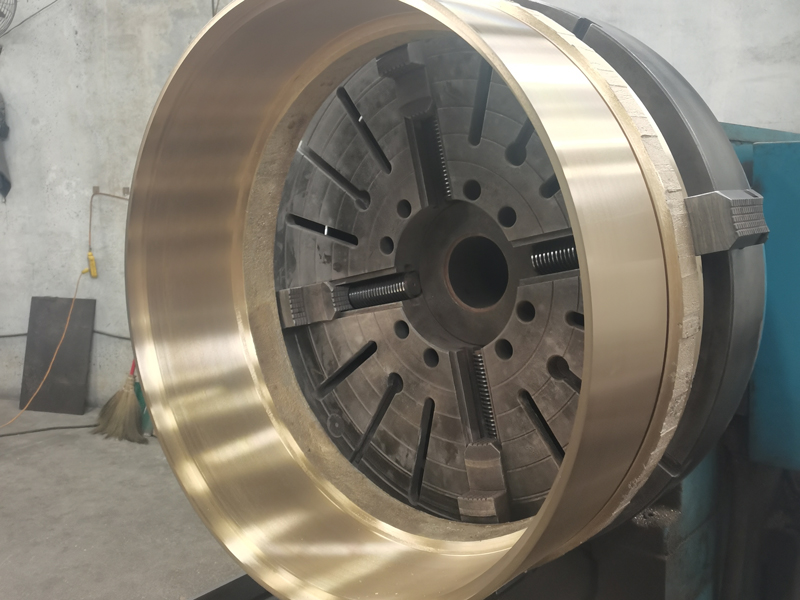

Centrifugal Casting

Centrifugal casting uses a high-speed rotating mold to evenly distribute molten metal under centrifugal force, forming a high-density metal layer. The advantages of this process include:

High material density, reducing pores and impurities, and improving wear resistance.

Good surface finish, reducing subsequent processing costs.

Suitable for mass production, with high efficiency and controllable costs.

Gravity Casting

Gravity casting relies on the self-weight of the molten metal to fill the mold, making it suitable for bushings with complex shapes or larger sizes. Its characteristics include:

Strong adaptability, capable of producing bushings of different specifications.

Simple process, suitable for small-batch custom production.

Lower cost, but density and strength are slightly inferior to centrifugal casting products.

Xinxiang Haishan Machinery has been deeply involved in the field of bushing manufacturing for many years, adopting advanced centrifugal casting and gravity casting technologies to ensure that every bushing product has excellent wear resistance and stability.

Xinxiang Haishan Machinery: Professional Bushing Manufacturing Expert

As a leading domestic mechanical parts supplier, Xinxiang Haishan Machinery has won the trust of many customers with its exquisite craftsmanship and strict quality control. Its bushing products are widely used in:

Engineering machinery (such as excavators, cranes)

Mining equipment (crushers, conveyors)

Agricultural machinery (tractors, harvesters)

Industrial transmission systems (reducers, motors)

The company uses high-precision CNC machine tools for processing to ensure the dimensional accuracy and surface finish of the bushings, while also providing customized services to meet the needs of different industries.

Conclusion

Although bushings are small, they are key to the stable operation of mechanical equipment. Whether centrifugal casting or gravity casting is used, high-quality bushings can significantly improve equipment performance and service life. With its robust technology and rigorous attitude, Xinxiang Haishan Machinery continues to provide customers with cost-effective bushing solutions.

If you are looking for a reliable bushing supplier, feel free to contact Xinxiang Haishan Machinery and let their professional technical team provide you with the optimal solution!

#Mechanical Equipment #Bushing Parts #Industrial Manufacturing #Mechanical Parts #Xinxiang Haishan Machinery