Industrial bronze products are widely used in many fields such as machinery manufacturing, electronics, and construction due to their excellent mechanical properties and corrosion resistance. In order to ensure the performance and reliability of the products, it is crucial to have a deep understanding of their production process and quality control.

Raw material selection

The first step in producing high-quality industrial bronze products is to select suitable raw materials. Bronze alloys are mainly composed of elements such as copper, tin, and lead, and their proportions will be adjusted according to specific application requirements. High-quality raw materials are the basis for ensuring the performance of the finished product.

Smelting process

Smelting is a key link in bronze production, which involves heating the raw materials to the melting point to form a uniform copper liquid. In this process, the temperature needs to be strictly controlled to avoid being too high or too low to ensure the uniformity of the alloy composition. In addition, adding an appropriate amount of deoxidizer can prevent the formation of bubbles, thereby improving the density of the casting.

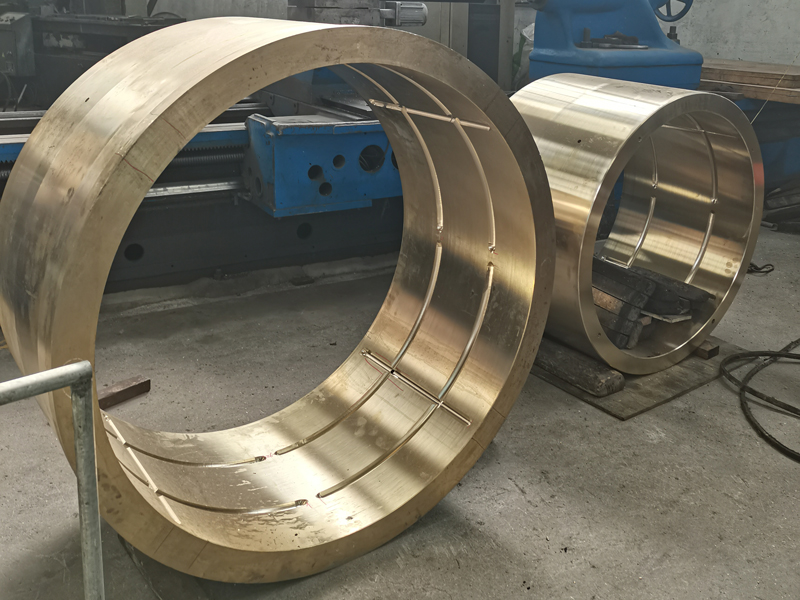

Casting technology

The choice of casting method directly affects the appearance and performance of the product. Common casting methods include sand casting, precision casting, and pressure casting. Selecting an appropriate casting process, combined with a reasonable mold design, can ensure the dimensional accuracy and surface finish of the casting.

Cooling and Post-processing

The speed and manner of cooling of castings are crucial to the quality of the final product. By controlling the cooling process, deformation and cracking of castings can be prevented. Post-processing steps, such as grinding, polishing and pickling, are used to improve surface quality, remove surface defects and ensure that the product meets technical requirements.

Quality Control

During the production process, strict quality control is an important link to ensure product performance. By adopting means such as microscopic inspection, hardness testing and chemical composition analysis, problems in production can be discovered and corrected in a timely manner. In addition, before the product leaves the factory, a comprehensive inspection is required to ensure that each bronze product meets the standards.

Technological Innovation and Environmental Protection

With the advancement of technology, the production process of bronze products is also constantly improving. For example, the use of advanced smelting equipment and casting technology can improve production efficiency and material utilization. At the same time, in the production process, attention should be paid to environmental protection, reducing waste and emissions to promote sustainable development.

In summary, the production process and quality control of industrial bronze products is a complex system engineering. From raw material selection, smelting, casting to post-processing, every link needs to be refined. Through effective quality control measures, the excellent performance of bronze products in industrial applications can be ensured, providing strong support for the development of related industries.